Yale Bridge Abutment Repairs

Yale Bridge Abutment Repairs

January 20 Progress Update

Crews have safely and successfully completed the following work:

- Crews completed non-critical aesthetic work to RTD’s bridge.

- Crews backfilled the walls and applied final coatings.

- A truck mounted attenuator was used to protect crews while working near traffic.

- Other parties may conduct further environmental remediation under the bridge.

Project Overview

The Regional Transportation District (RTD) is working to complete emergency repairs to the Yale Street light rail bridge abutment after a fuel tanker crashed into the structure on Thanksgiving day. The non-RTD crash damaged the bridge’s mechanically stabilized earth (MSE) wall. Safety-critical repairs along with all necessary safety tests and inspections were completed on Tuesday, Dec. 23. Light rail service has resumed on both sets of track. Non-critical aesthetic work to the bridge will continue during normal service.

Repair Phases

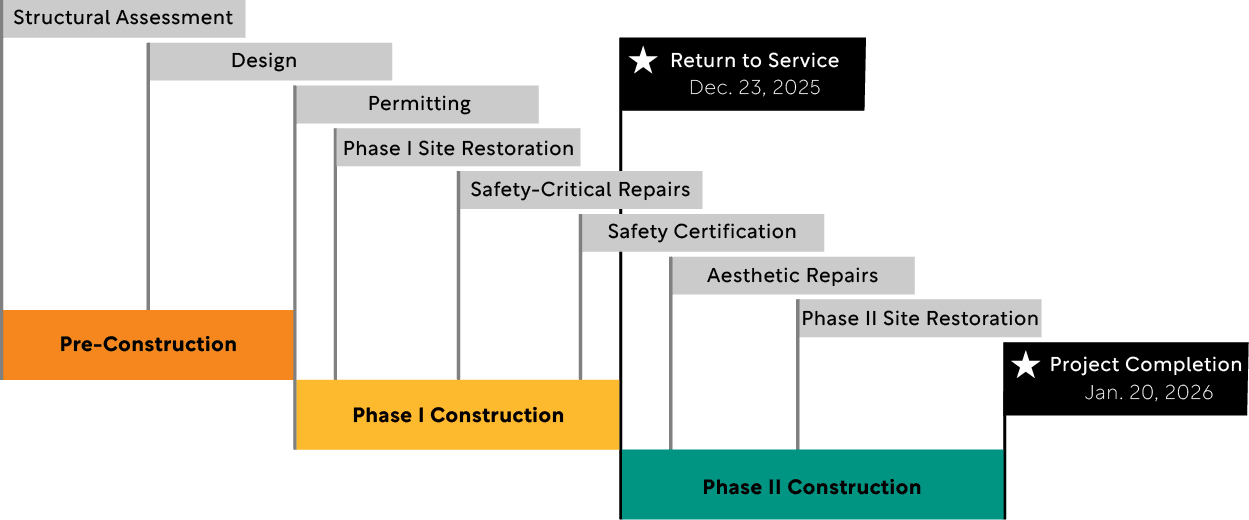

The timeline above provides a breakdown of the phases for repair work and the milestones crews are working towards in each phase. Milestones shown in in grey are complete.

Project Updates

December 17th 2025

Crews have safely and successfully completed the following work:

- Crews removed damaged bridge abutment wall panels.

- Crews installed wire mesh and shotcrete to shore up the abutment walls prior to soil nail installation.

- Crews marked locations for future soil nails.

- Environmental hazmat teams investigated inlets to identify residual fuel spill.

- Quality inspectors performed material testing in accordance with the quality control plan.

December 19th 2025

Crews have safely and successfully completed the following work:

- RTD Safety coordinated with crews to ensure compliance and worker safety.

- Crews drilled pilot holes for soil nail installation.

- Crews installed and grouted 18 soil nails to stabilize the abutment wall.

- Crews utilized injected foam and grout to prevent soil loss and ensure the structural integrity of the wall.

- Quality inspectors took samples of grout to perform compressive strength testing.

December 22nd 2025

Crews have safely and successfully completed the following work:

- RTD Safety coordinated with crews to ensure environmental compliance and worker safety.

- Crews installed and grouted 9 soil nails to stabilize the abutment wall.

- All soil nail work has been completed.

- Crews completed excavation work to the walls leveling slab.

- Crews have begun installing strip drains and welded wire fabric.

- Quality inspectors took samples of grout to perform compressive strength testing.

December 23rd 2025

Crews have safely and successfully completed the following work:

- The contractor performed the pull testing of the verification soil nail, with passing results.

- Crews applied shotcrete to the face of the wall repairs.

- Contractor survey crews verified that the rail did not move during the construction of the safety critical work.

- RTD train testing was successfully completed.

- Service was restored Tuesday afternoon, December 23. Trains are operating on both tracks and have returned to 15-minute frequencies.

January 12th 2026

Crews have safely and successfully completed the following work:

- Crews finished setting all wall fascia panels and completed the placement of in-fill concrete.

- Crews installed the concrete leveling pad and set precast coping panels.

- A passing weather front caused a temporary work suspension from Jan. 8-9 for safety and site cleanliness, with operations resuming Saturday, Jan. 10.

- Crews continued quality control practices to ensure the final construction meets all technical specifications.

Customer Tools

Service Alerts

RTD encourages customers to sign up for Service Alerts to receive text and email notifications about future and real-time disruptions that impact specific bus routes, rail line, stop or station.

Subscribe for UpdatesNext Ride

Customers are also encouraged to use the Next Ride web app to plan trips, view active Service Alerts, and see bus and train locations in real time.

Access Next Ride HereCustomer Care

For additional route and schedule information, or questions on impacts to service, RTD’s Customer Care agents are available 6 a.m. to 8 p.m. on weekdays, and 9 a.m. to 6 p.m. on Saturdays, Sundays and holidays by calling 303.299.6000. For Spanish, press 2. For assistance in all other languages, please tell the Information Specialist what language you speak and stay on the phone while they connect to an interpreter.